Revolutionizing Building Construction 3D Laser Scanning Technology

- Home

- Blog

3D Laser Scanning in Construction: Things You Need to Know

It is a technology that uses lasers to accurately measure and map the surface of a building’s physical objects or environments. It is a non-invasive, efficient, and cost-effective way to capture precise data about a construction site or project. In the past, construction professionals relied on traditional surveying methods to gather data about the site. Methods such as total stations, photogrammetry, and theodolites, were time consuming and required extensive setup. 3D laser scan, on the other hand, allows for quick and easy data collection with a high degree of accuracy. Light Detection and Ranging scanners, also known as LiDAR scanners is a form of portable 3D laser scanning equipment for buildings to capture data.

Table of Contents

ToggleHistory of 3D Laser Scanning

The history of 3D laser scanning and survey engineering in construction dates back to the 1970s, when the first laser scanners were developed. These early scanners were large and expensive and were primarily used in military and industrial applications. In the 1980s and 1990s, advances in technology led to the development of smaller and more affordable laser scanners, which began to be used in the construction industry for laser surveys.

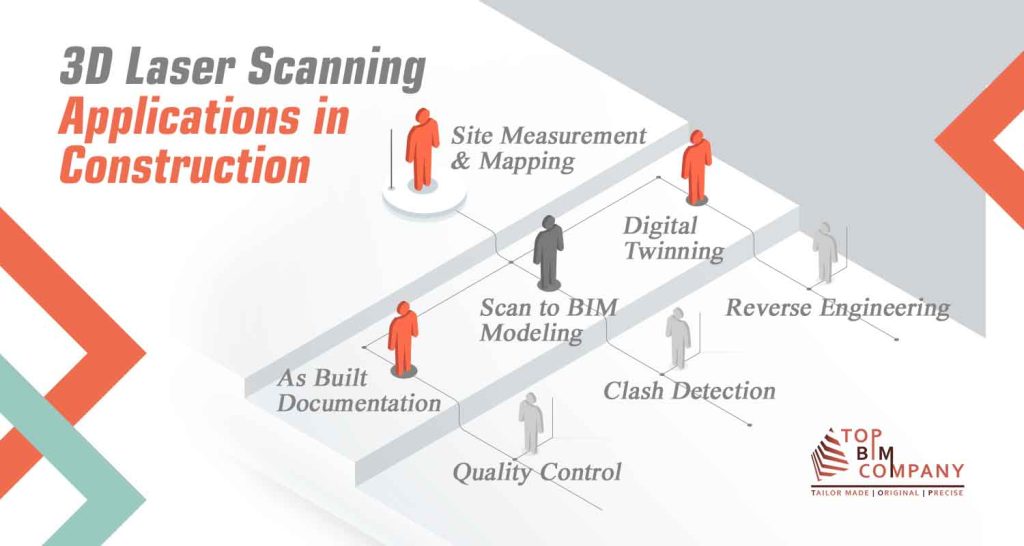

Initially, this technology was used primarily for site measurement and mapping, as it was a faster and accurate alternative to traditional surveying methods. As the technology improved, it began to be used for a wider range of applications, such as as built documentation, quality control, and clash detection.

For precise & quality assured 3D Laser Scan of buildings

Our BIM Professionals will provide a customized solution & cost estimation for your project.

How 3D laser scanning works?

3D laser scanners use lasers to measure the distance between the scanner and the surface of an object or environment. These lasers are emitted and reflected off the surface, providing data on the shape and contours of the object or environment.

The 3D scanner processes this data and creates a 3D point cloud, which is a digital representation of the building. This point cloud data can then be used to create a 3D BIM model with the help of Scan to BIM methodology using the BIM software Autodesk Revit.

The implementation of laser scanning in buildings consists of a number of steps.

- Setup: The 3D laser scanner is set up at the desired location and is oriented toward the environment that needs to be scanned.

- Data collection: The 3D laser scanner for buildings emits lasers and measures the distance between the scanner and the surface. This data is collected and processed to create a 3D point cloud.

- Data processing: The 3D point cloud data is processed using BIM software like Autodesk Revit to create 3D model of the building.

- Analysis: The 3D model can be used to analyze the building and extract valuable information, such as dimensions, geometry, and spatial relationships. This information can be used for a variety of purposes, such as project planning, quality control, and clash detection.

- Presentation: The 3D model can be presented to the clients and other stakeholders in a variety of formats such as 2D drawings, 3D models, architectural renders, and walkthroughs. This allows for easy communication and visualization of the building or the facility.

Advantages of Laser Scan 3D Modeling

- Increased accuracy: It is highly accurate, with an average accuracy of 2mm. This accuracy is important in construction, where even small discrepancies can have a significant impact on the final project.

- Efficiency: It is much faster than traditional surveying methods, allowing for the collection of large amounts of data in a short period of time. This can help save time and resources on construction projects.

- Cost-effectiveness: It’s survey is often more cost-effective than traditional surveying methods, as it requires fewer personnel and less setup time.

- Reduces manual labor: Compared to traditional surveying methods for buildings it only requires only one person to operate the scanner.

Use cases of 3D laser scan in construction

- Site measurement and mapping: This techniques can be used for quick and accurate terrestrial scanning of the construction site, providing valuable data for project planning and management.

- As built documentation: Laser scanning survey equipment can be used to create as built documentation of a construction project, providing a record of the project’s progress and any changes that have been made.

- Quality control: It can be used to ensure that a construction project is being built to the correct specifications and tolerances.

- Scan to BIM modeling: The point cloud data acquired using the laser scanning process is used to create as built 3D BIM Model of the building using Scan to BIM methodology with BIM software like Autodesk Revit. These Scan to BIM As-built Models are used for renovation, remodeling, and facility management.

- Digital twinning: The as built 3D BIM models can be converted in to Digital Twins by incorporating Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT). Digital Twins are used for remote and real time facility management.

- Clash detection: Laser scanning can be used to detect conflicts or clashes between different systems or components in a construction project, helping to prevent costly mistakes.

- Reverse engineering: For retrofitting equipment in hard-to-reach and hazardous spaces in industrial buildings, laser scan reverse engineering technique is employed to get precise data.

Case studies: 3D Model Scan Projects

There are many examples of laser scanning being used successfully in construction projects. Some examples include:

- The construction of London Cross-rail project, where laser scanning is used to ensure that the project was being built to correct tolerances and to detect any potential clashes between systems.

- The restoration of Notre Dame Cathedral in Paris, where 3D laser scans for cultural heritage was used to create a digital model of the cathedral’s intricate stone carvings and to document the progress of the restoration work.

- For the construction of Dubai World Central airport in Dubai, 3D laser digital scanning for surveying was used to accurately measure and map the construction site and to create as built documentation of the project.

- Laser Surveying archaeology services are employed at the archaeological site of Mohenjo-Daro to document the historical site and its artifacts.

Future of 3D laser scanning in construction

- Integration with other technologies: It will be integrated with other technologies, such as BIM (Building Information Modeling) and drones, to provide even more comprehensive data and insights about construction projects.

- Increased automation: The use of artificial intelligence and machine learning may lead to increased automation in the processing and analysis of 3D scan data, allowing for even faster and more efficient data collection and analysis.

- Virtual reality applications: The data can be used in the development of virtual reality applications of construction, allowing for immersive and interactive experiences of construction projects.

Add 3D Building Scanning to Your Surveying Capabilities

3D laser scanning is a valuable tool in the construction industry, providing accurate, efficient, and cost effective data collection and analysis. As the technology continues to evolve and improve, it is likely to play an even larger role in construction projects in the future.

The use of laser scanning as the initial stage of building projects is increasing. The time to consider including such tools in your building projects is now if you haven’t already done so. With automated systems for building documentation in place and data captured and distributed automatically, construction firms can concentrate on meeting deadlines and staying under budget.

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.