Shop drawings are detailed plans that are used by contractors and fabricators to construct and install building components. They typically include information such as dimensions, materials, finishes, and assembly instructions. Shop drawings are prepared through CAD software application.

Table of Contents

ToggleHowever, in recent years, building information modeling (BIM) has become increasingly popular for shop drawing creation.

BIM is a digital process for creating and managing building data. It allows users to create and share 3D models of buildings, which can be used to coordinate design, construction, and operation. BIM models can also be used to generate shop drawings, which can be more accurate and efficient than traditional CAD-based methods.

Also Read – Ultimate Guide to Create Construction Shop Drawings

How BIM is advantageous over CAD in shop drawings preparation?

BIM offers a number of advantages over CAD for shop drawing preparation, including:

- Accuracy: BIM models can be more accurate than CAD drawings, as they are created using 3D parametric modeling. This means that changes made to the model will automatically be reflected in the shop drawings.

- Efficiency: BIM can help to streamline the shop drawing process by automatically generating drawings from the 3D model.

- Collaboration: BIM makes it easier for different stakeholders to collaborate on shop drawings. For example, architects, engineers, and contractors can all view and share the same 3D model, which can help to reduce coordination issues.

Getting Started with BIM:

- Select BIM tool: Choose the right software for your needs.

- Create BIM model: Import CAD drawings or build from scratch.

- Set up BIM project: Define roles and responsibilities.

- Develop shop drawing workflow: Create a consistent and efficient process.

- Create and issue shop drawings: Use the BIM model to generate accurate drawings.

Shop Drawing Creation in BIM

Once you have created a BIM model and set up a BIM project, you can start creating shop drawings. To do this, you will need to extract the relevant information from the BIM model and generate 2D drawings.

There are a number of different ways to extract shop drawings from BIM models. Section box tool allows you to create 2D drawings of cross-sections of the BIM model.

You can also use the extract view tool to create 2D drawings of specific elements in the BIM model.

- Extracting Shop Drawings from BIM Models: Once you have extracted the relevant information from the BIM model, you need to generate 2D drawings. This can be done using the BIM software itself, or by exporting the data to a CAD software application. You could set 2D drawings on sheets for shop drawing creation rather than importing from CAD.

- Annotating and Detailing: Once you have generated the 2D drawings, you need to annotate and detail them. This involves adding dimensions, notes, and other information to the drawings. It is important to be consistent with your annotation and detailing practices. This will help to ensure that the shop drawings are easy to read and understand.

- Quality Control and Validation: Once the shop drawings have been annotated and detailed, they need to be checked for quality and accuracy. This should be done by a qualified individual, such as a BIM manager or architect.

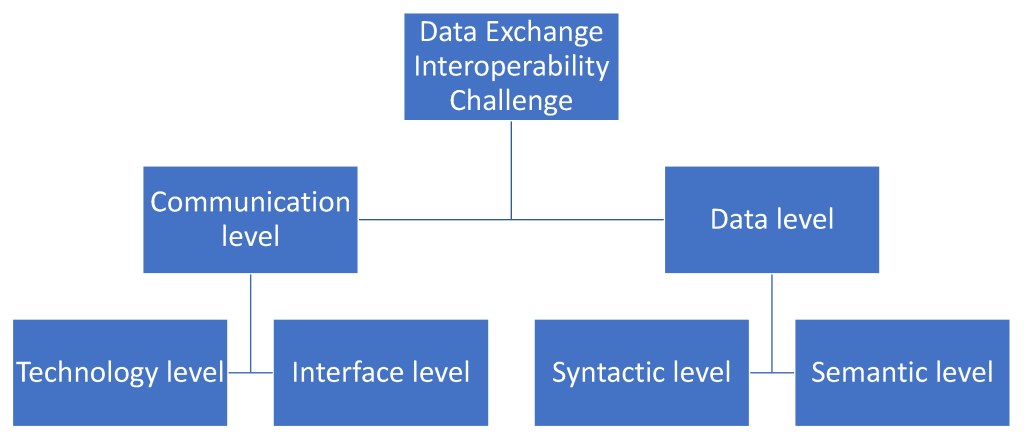

Interoperability and Data Exchange

Interoperability is the ability of different software systems to exchange data and work together seamlessly. This is important for BIM for shop drawings, as it allows different stakeholders to use the same BIM model to create and review shop drawings.

There are a number of different ways to achieve interoperability with shop drawing data.The most common workflow of data exchange between CAD and BIM drawing formats is to use a neutral file format. This is a file format that is supported by both CAD and BIM software and can be used to transfer data between the two types of programs without losing any information.

The most common neutral file format for CAD and BIM data exchange is Industry Foundation Classes (IFC). IFC is an open standard file format that is supported by most major CAD and BIM software applications.

To exchange data between CAD and BIM using IFC, the following workflow is typically used:

- Export the CAD model to IFC – This can be done from most CAD software applications.

- Import the IFC file into the BIM software application – This can be done from most BIM software applications.

- Review imported model in BIM software application – It is important to review the imported model to ensure that all data has been imported correctly.

- Continue working on the model in the BIM software application – Once the model has been imported and reviewed, you can continue working on it in the BIM software application.

Shop Drawing Review Process

Shop drawing review is a critical part of the construction process. It ensures that fabricated components meet the design intent and fabrication standards.

The review process typically follows these steps:

- Submittal schedule: The contractor sets a schedule for submitting shop drawings for review.

- Design delegation: The contractor specifies which shop drawings require the review and seal of a delegated design engineer.

- Contractor’s review: The contractor reviews and approves all shop drawings before submitting them to the professional of record.

- Reviewing for design intent only: Consultants review shop drawings to verify if they correctly represent and implement the design specified in the construction documents.

- Using supplemental instructions: The reviewer notes if a particular dimension needs field verification and issues supplemental instructions instead of simply marking the information in the shop drawing.

- Confirmation of shop drawing review: The registered professional record stamps the shop drawings to certify that they have been reviewed.

- Coordination, clarification, and making changes: If directed by the registered professional of record, the contractor makes all changes to the shop drawings and resubmits them.

The shop drawing review process is important for ensuring the quality and accuracy of fabricated components. By following these steps, contractors and reviewers can work together to identify and address any issues early in the construction process.

BIM for Pre-fabrication

BIM shop drawings for pre-fabrication are detailed drawings of prefabricated components that are created using BIM software. BIM shop drawings are used to communicate the design intent to the fabricator and to ensure that the components are manufactured to the correct specifications.

BIM shop drawings are an essential part of the pre-fabrication process. By using BIM shop drawings, fabricators can create high-quality components that are accurate, coordinated, and efficient to install.

BIM shop drawings typically include the following information:

- Dimensions and tolerances

- Materials and finishes

- Assembly instructions

- Quality control requirements

BIM shop drawings can be used to pre-fabricate a wide range of components, including:

- Structural steel

- Precast concrete

- MEP (mechanical, electrical, and plumbing) systems

- Millwork

- Cabinetry

- Appliances

Here are some examples of how BIM shop drawings can be used for pre-fabrication:

- A structural steel fabricator can use BIM shop drawings to generate cutting instructions for the steel beams and columns.

- A precast concrete fabricator can use BIM shop drawings to create molds for the precast concrete panels.

- An MEP contractor can use BIM shop drawings to pre-fabricate ductwork and piping assemblies.

- A millworker can use BIM shop drawings to pre-fabricate cabinets and other millwork components.

Future Trends in BIM for Shop Drawings

Asset Management for Thorough Development Right from the Start

BIM can be used for asset management throughout the lifecycle of a building. This means that the BIM model can be used to track and manage all of the building’s data, including its shop drawings. Asset management can help to ensure that the building is maintained and operated efficiently and effectively.

Additionally, asset management can help to extend the lifespan of the building. 6D BIM approach of asset management would provide more intelligence to shop drawings.

Manufacturing-Oriented BIM Content

Manufacturing-oriented BIM content is BIM content that is specifically designed for use in manufacturing and prefabrication.

This type of content includes information such as fabrication tolerances and CNC machining instructions. Manufacturing-oriented BIM content can help to improve the efficiency and accuracy of CNC machining and prefabrication.

Additionally, it can help to reduce the cost of manufacturing and prefabrication. With a manufacturing-oriented approach, shop drawings would have specifications that would be market ready and comprehensible by on-site workers.

Overall, BIM has the potential to revolutionize the way that shop drawings are created and used. By improving communication, coordination, accuracy, and efficiency, BIM can help to reduce the cost and time overruns that are common on construction projects. BIM can also help to improve the quality of construction and to reduce the environmental impact of buildings.

Also Read: – BIM vs CAD in Construction

CAD is generally used for shop drawings purposes, but it is high time that the industry shifts to a BIM approach. BIM offers a number of advantages over CAD, including:

- Improved accuracy: BIM models are more accurate than CAD drawings because they contain more information about the building, such as the materials and construction methods.

- Better coordination: BIM models can be shared and collaborated on by different stakeholders, which helps to improve coordination and reduce errors.

- Greater efficiency: BIM models can be used to automate many of the tasks involved in creating shop drawings, such as generating material lists and cutting instructions.

- As the industry continues to adopt BIM, we can expect to see more and more shop drawings being created using BIM software.

Our Services

Latest Post

Get A Free Quote

BIM Construction is the Future

Building information modeling (BIM) is the future of building design and construction. Get in touch with our BIM Experts.