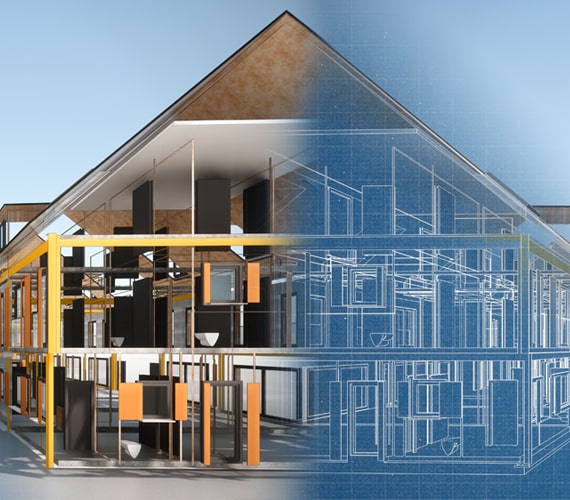

Innovative technology integrated with 3D laser scanning & BIM enable precise & virtual representation of building.

A digital twin is a virtual replica of a real-world entity that mirror and assesses its real-world counterpart. Accurate BIM models and real-time simulations of the construction activities are made possible by digital twinning. Our engineers and facility managers use the virtual 3D BIM model to plan rehabilitation and retrofit projects as it accurately duplicates the built building in its current state.

Digital twinning is a dynamic depiction of an actual object used in the building, engineering, and architectural industries. Real-time data and design are combined by technology to enable well-informed decision-making. Through digital twin technology, our data-based 3D modeling procedure ensures thorough insight into an actual planning and forecasting process. BIM integrated digital twin consortium provides essential development and limitless options to the AEC stakeholders through automation, data sharing, and manufacturing process.

Our certified BIM & 3D laser scanning professionals work diligently to deliver digital twin models that are quality-assured and made with progressive technology & equipment like 3D laser scanning. We provide precise constructed digital twins that are produced by BIM software applications like Autodesk Revit and Navisworks.

For visualization, documentation, analysis, progress tracking, and planning.

Organizations are acquiring more data visibility with the help of digital twin simulation, and they can use these insights to affect how customers and workers feel. AEC clients get ongoing information about how their products are doing in the field. These insights enable them to iterate and improve goods more quickly and effectively.

BIM engineers test product performance prior to actual prototyping by using digital twins in conjunction with digital models and simulation tools. This results in significant cost and time reductions for expensive products. Time-to-market is shortened, avoiding late-stage redesign through the use of digital twins.

We have experience in creating BIM models for design, engineering, and construction projects. Through a streamlined method, our team systematically ensures accurate digital twin modeling for building management & refurbishment project.

Our professionals use methods like 3D laser scanning to collect precise point cloud data.

BIM helps to process the point cloud data that the experts have collected. Using the data, the Scan to BIM modelers produce a data-rich model.

After the 3D digital twin model has been carefully assessed, the final product is ready.

The final output is ready after the 3D digital twin model is properly evaluated

Enabling virtual support and troubleshooting through the use of digital twin solutions, skilled engineers are no longer physically required to be present at your location.

With digital twins, there are potential along the entire value chain.

With digital twin technologies, businesses see the lead times in supply chain.

Operational efficiencies along the value chain are provided by digital twins.

Experts located off-site view operating equipment using digital twin technology.

Digital twin technologies help your company in the short, medium, and long terms. Digital twin usage is also a developing trend. It’s time to analyze and use this novel technology if you want to stay competitive. Contact us for digital twin services.

A physical object's functionality, characteristics, and behavior are digitally replicated in the virtual environment to create a digital twin of the physical asset. Smart sensors that gather data from the product are used to produce a real-time digital depiction of the asset.

BIM models and digital twins are both digital representations of real locations. The primary distinction between the two is that whereas digital twins allow for virtual engagement with an asset, BIM 3D models are used to visualize the design and development of an asset.

The creation of digital twins for physical items using 3D modeling is an example of a digital twin. It offers a mechanism to bring physical objects into the digital world and can be used to view the status of the real-world object.

Since the physical asset is being monitored in real time, Autodesk digital twins can assist avert major accidents. It is possible to monitor existing assets where a digital model has not yet been made by fusing 3D scanning with sensors.